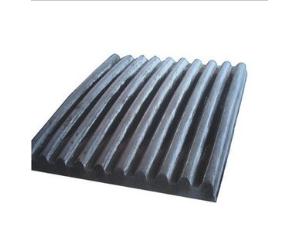

ductile iron casting

- Product Details

- Company Profile

ductile iron casting, grey iron casting, steel casting

Basic Info.

Name: OEM and Customized Sand Casting Material:Grey Iron, ductile iron , Steel

Surface Treatment: Sand Blast, Polishing, Powder Coating Application: Machinery Parts

Machining: CNC Machining Standard:AISI

Certification: SGS, CE, ISO 9001:2000, ISO 9001:2008 Sand Core Type: Sodium Silicate Sand Core

Casting Method: Directional Crystallization Surface Roughness: Ra0.2

Type: Clay Dry Sand Lead Time:20-30 Days

Packaging: Polybag + Carton + Pallet or wooden Case Tolerance:Normally +/- 0.5mm or as Per Your Drawing

Secondary Machining: Milling, Tapping, Grinding Weight Range:0.5kg-500kgs for Sand Casting

OEM / ODM: Completely as Per Your Sand Casting Drawing Casting Type:Grey Iron Sand Casting

Manufacturing Processes: Grey Iron Sand Casting + CNC Machining Export Markets:Global

Additional Info.

Trademark: QINGHUI / OEM Service Packing: Based on Your Requirement

Origin: Shanxi, China Production Capacity:30, 000PCS/Month

Product Description

OEM Grey Iron Sand Casting, Ductile Iron Sand Casting

ISO 9001Certificate,CE Certificate

Engaged in OEM order & small orders acceptable

Production Capacity: 150,000pcs/Month

1) Manufacturing Processes: Sand casing + Machining + Heat Treatment + Surface Finish

2) Materia availablel: Ductile iron, grey iron, alloy steel, stainless steel, brass etc...

3) Machining: Turning, cutting, milling, grinding, drilling, tapping;

4) Equipment: CNC lathe;

5) Tolerance for Sand Castings: +/-0.5mm;

6) Surface Finishing Available: Polishing, Anodizing, Hard Anodizing, galvanized, ENP, Chrome plating, Powder Coating and Painting;

7) Quality Control: Internal inspection, the third party inspection or customers inspect by themselves

8) OEM order: The parts can be made completely based on your specifications such as drawing, design, sample etc

9) Weight range: 0.5kg---5000kgs

9) Delivery time: Depend on the order qty;

QC Procedure:

1) Material Examination

2) Manufacturing Processes Supervision

3) Inspection For The Batch Production

4) Random Inspection

Our Advantages:

10 years experience in manufacturing and exporting

OEM and customs service

All the parts can be manufactured according to the drawings, samples or specific industry standard

Professional and strong engineering team guarantee high quality with reasonable and low price

Advanced-level equipments

Full material testing process and quality control system

Delivery on time

Software: Pro/E, Auto CAD, Solidwork, CAXA, UG, etc.

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier