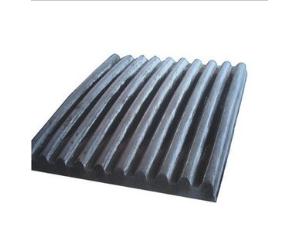

grey iron casting spare parts, replacement parts

- Product Details

- Company Profile

Material: Ductile Iron, Carbon Steel, Grey iron Sand and investment casting(precision casting)are all avalable

Model NO.: custom sand casting Material: All Alloy, Grey Iron

Surface Treatment: Sand Blast, Polishing/Powder Coated / Painted

Application:Machinery Parts Machining:CNC Machining

Standard:AISI Certification:ISO 9001:2000, ISO 9001:2008

Sand Core Type:Sodium Silicate Sand Core Casting Method: Directional Crystallization

Surface Roughness:Ra0.2 Type:Clay Dry Sand

Technology:Sand Casting Color: Black or as Request

Tolerance:+-0.5mm or as Drawing Post-Process:Heat Treatment

OEM and ODM: 100% with Drawing of Grey Iron Casting

Secondary Machining: Milling, Tapping, Grinding

Welcome:Custom Grey Iron Casting Parts

Custom:Grey Iron Casting for Sand Casting Export Markets:Global

Additional Info.

Trademark: QINGHUI Packing:Wooden Crate or by Customer′s Requirement

Origin:Jincheng, Shanxi, China Production Capacity:1000tons Per Month

Product Description

OEM grey iron casting for sand casting

OEM is acceptable.

Good quality and low price

Contace us without hesitation

* Material: Ductile Iron, Carbon Steel, Grey iron

* Sand and investment casting(precision casting)are all avalable

* Software for drawing: PRO/E, Auto CAD, UG, CAD, PAF and Solidwork 2008 flow analysis

* Further machining work: Turning and cutting, milling, grinding, drilling, reaming and threading

* Equipment: CNC center, CNC center and lathes.

* Surface finish process: Shot blast, chromate plating, power coated and anodizing

* OEM/ODM parts range: auto parts, electronic parts, furniture parts, home appliance and other industrial uses

* Process: CAD surface, matel processing, surface plating, QC testing and packaging

* Made according to customers' drawing, sepecification or/ and samples

* Castng capacity: 30000pc/ month

(1)Incoming material inspection

(2)Inspection of work-in-progress

(3)Finished product inspection

(4)Random warehouse inspections

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier