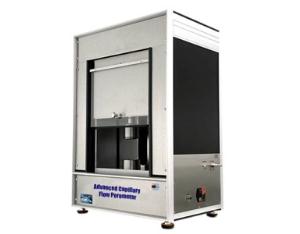

Complete Filter Cartridge Analyzer

- Product Details

- Company Profile

Complete Filter Cartridge Analyzer automatically analyzes the perforation of the entire filter cartridge of various geometries. The complete filter cartridge analyzer is ideal for quality control and R & D environments.

Complete Filter Cartridge Analyzer automatically analyzes the perforation of the entire filter cartridge of various geometries. The complete filter cartridge analyzer is ideal for quality control and R & D environments. It is fast, accurate and non-destructive. And it is used in any industry where the filter cartridge is used. The specific examples include automation, filtration, nonwovens and pharmaceuticals. The test consisted of foaming point, pore size distribution, average pore size, gas, liquid and Frazier permeability, and filter integrity. The design of the sample chamber allows the use of a wide range of diameter and length of the filter cartridge. With a non-destructive test for 10 minutes, complete filter cartridge analyzer is ideal for quality control and R & D research.

Application

The complete filter cartridge analyzer is ideal for quality control and R & D environments. The device is fast and accurate and non-destructive. It is used in any industry where the filter cartridge is used.

1. Automotive Manufacturing 6. Detoxification

2. Pharmaceutical Industry 7. Nonwovens

3. Biotechnology 8. Pollution control

4. Filter 9. Sintered metal

5. Ceramics

Operation Principle

Place a fully wetted filter cartridge in the sample chamber and seal the sample chamber. And then flow the gas to the filter. When the pressure reaches the point at which the capillary action can be overcome in the hole (maximum hole), regard the point as the bubble point. After determining the bubble point, increase the pressure and measure the flow until all the holes are empty and the filter element is considered dry.

Features

Þ Windows-based software handles all control, measurement, data collection, and report generation.

Þ complete manual control also possible.

Þ Compatible with Windows 95 or higher.

Þ During the operation, the current chart test shows the test status and the results

Þ Non-destructive test.

Þ The test length is about 10 minutes for each sample.

Þ accept a variety of geometry of the complete filter cartridge.

Þ Transparent sample room for visual judgment.

Þ Need minimal maintenance

Average pore size Pore size distribution

Foaming point (maximum hole) Integrity

Gas and liquid Frazier Permeability

Gurley

Head test

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier