Supply crankshaft repair, crankshaft wear laser cladding repair

- Product Details

- Company Profile

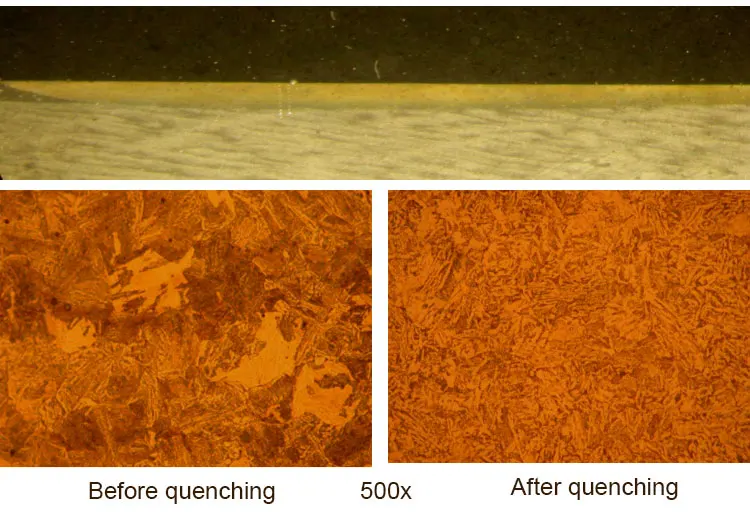

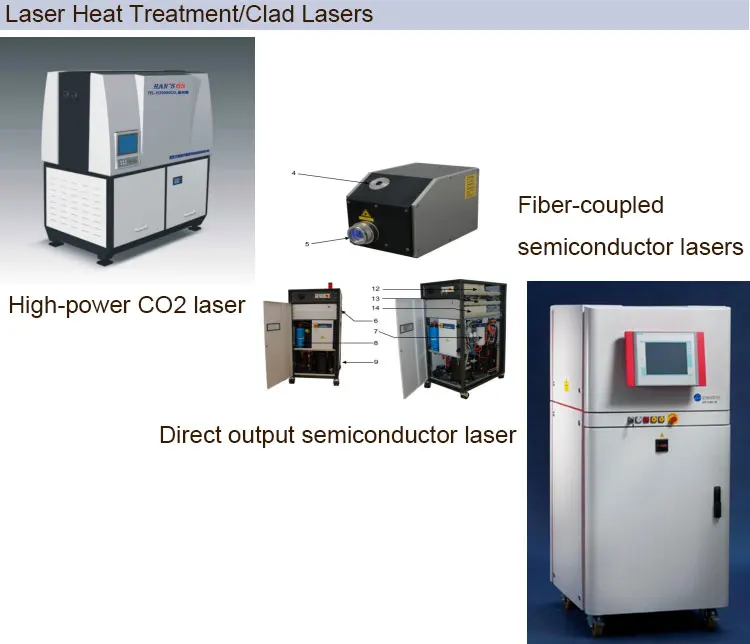

Laser processing is an advanced manufacturing technology developed at the end of the last century. It is used in various fields such as machinery manufacturing, metallurgy, transportation vehicles, molds, petrochemicals, exploration, electricity, textile, aerospace and other fields. The main features of laser surface treatment products are: high hardness, high efficiency, good quality, and can achieve high abrasion resistance, high strength, high corrosion resistance, high red hardness and other properties that cannot be achieved by conventional techniques, and cannot achieve conventional methods. The heat treatment or repair method is achieved.

Supply crankshaft repair, crankshaft wear laser cladding repair

Laser processing is an advanced manufacturing technology developed at the end of the last century. It is used in various fields such as machinery manufacturing, metallurgy, transportation vehicles, molds, petrochemicals, exploration, electricity, textile, aerospace and other fields. The main features of laser surface treatment products are: high hardness, high efficiency, good quality, and can achieve high abrasion resistance, high strength, high corrosion resistance, high red hardness and other properties that cannot be achieved by conventional techniques, and cannot achieve conventional methods. The heat treatment or repair method is achieved.

Wuhan Hans Goldensky Laser System Co., Ltd.

Location:Wuhan,Hubei,China

Business Type:

Main Products:Laser Cutter, Metal Laser Cutting Machine, Fiber Laser Cutting Machine, YAG Laser Cutting Machine, Laser Hardening Machine, Laser Perforating Machine, Laser Cladding Machine, Laser Welding Machine

Wuhan Hans Goldensky Laser System Co., Ltd is subsidiary company of Han's Laser Technology Industry Group Co., Ltd, (stock code: 002008). We are high-tech enterprise specialized in R&D, manufacture and sales for complete equipment of high-power laser source, laser cutting, laser welding, laser fusion covering, laser heat-processing and high-speed laser punching machine. We also provide automatic processing solving plans.

Company has been successively undertaken the national development and reform commission (NDRC) national high-tech industrialization demonstration projects, the top ten key projects in Hubei province, Wuhan city top ten industrial projects of science and technology, and other government science and technology projects, including three products listed as a key project of national torch plan by the national ministry of science and technology. We successively obtains the national innovation fund, the electronic information industry development fund and a number of special fund support of Hubei province and Wuhan city, to be listed as the key innovation enterprise in east lake development zone, the key support leading enterprise in "large-scale laser equipment system integration and the new type laser manufacturing field" in Wuhan's 11th five-year plan.

Most of the products of our company has fully independent intellectual property rights, widely used in steel metallurgy, petroleum, tobacco, automobile, machinery, aerospace, chemical, home appliances and other manufacturing industries. In the future, the company will continue to be based on innovation of new and high technology, using its own technology advantages to contribute to the industrialization development of laser processing complete equipment.

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier