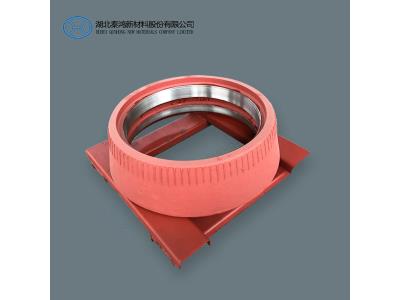

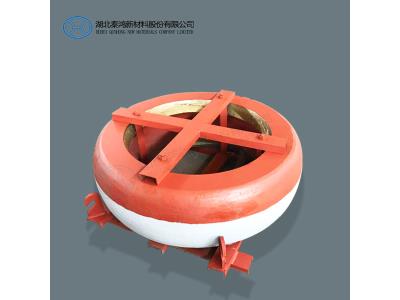

Cement plant raw mill,cement mill MMC Roller tyre,ceramic roller tyre

- Product Details

- Company Profile

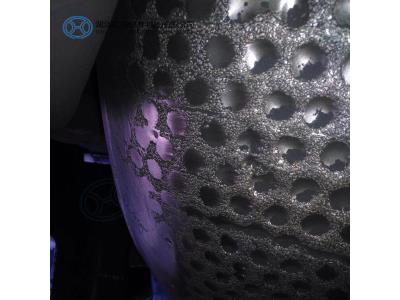

Production standard ASTM A532 EN 12513 GB/T8263 Material Cr18-28%+ refractory oxide Hardness 60±2 HRC(matrix) 1. It is a metal matrix composite material composed of alloy and ceramic, which is completed by special casting and heat treatment process 2, both wear resistance of ceramic and plastic toughness of metal 3. Prolong the service life of castings and reduce the maintenance and replacement time 4, repairable, reduce procurement costs, reduce power consumption 5, the surface honeycomb structure, reduce the relative sliding of work and materials, high hardness, good wear resistance, ventilation resistance and vibration are also significantly reduced, wear uniform surface, greatly prolonging the service life of the casting

Wear-resistant parts produced by Hubei Qinhong, the Lifespan is 10% longer than other similar domestic products, its price performance is higher than the imported products,completely replaced the imported roller segment,liner and other wear parts. Products have been exported to Russia, Germany,Pakistan,Costa Rica,Argentina, Greece and other countries.

Our company produces various kinds of imported and domestic roller segment and the table segment for vertical mills, such as FL Smidth ATOX type, Loesche LM type,GEBR. PFEIFFER,MPS type, RM type, CKP type,MLS type,MPF type,TRM type, HRM type, ZGM type,HP and so on.

Experience Member

Experience Member 0

0 Chinese

Supplier

Chinese

Supplier