Lift/Piston Check Valve

- Product Details

- Company Profile

Lift check valves are also called piston check valves. They are essentially globe valves without the stem and top works, allowing the disc to respond to flow rates and direction. The disc has linear movement and is typically body-guided with conical seating surfaces. Springs can be added above the disc to provide more closure force when the disc returns to its closed position. Some manufacturers include externally attached equalizer piping to increase the disc opening with lower flows. The equalizer pipe is an open-pressure communication device that maintains equal pressure above the disc and in the piping downstream of the disc. Depending on the valve body configuration (Y-pattern, angle, or T-pattern), the pressure drop could be close to that of a tilting disc check valve or much higher. The disc of this check valve design is stable in any open position and can be used with a wide range of flow rates.

Cast steel piston check valves are widely used in the industries of oil, chemical, medicine-made, fertilizer, city construction, etc. Seat seal surface overlaid with wearing resistant hardened alloy to be matched with disc seal surface; the stem is specially treated to ensure its strength, rigidity, corrosion resistance and abrasion resistance. Valves are available in a complete range of body/bonnet materials and trims, which are widely used for the medium of water, steam, oil product, nitric acid, acetic acid, oxygenation, etc.

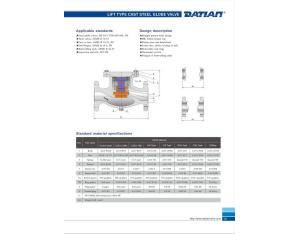

Applicable Standard

Design Standard: BS 1868, ASME B16.34, API 6D, DIN2533

Face to Face: ASME B16.10, API 6D, EN 558, DIN 3202

End Flange: ASME B16.5, ASME B16.47, DIN2501, DIN2533

Buttwelding Ends: ASME B16.25, DIN3239

Inspection and Test: API 598, DIN3230

Products Range

Size: 2" ~ 24" (DN50 ~ DN600)

Rating: ANSI 150lb-1500lb

Body Materials: Carbon Steel, Stainless Steel, Alloy Steel, Duplex Steel

Trim: Per API 600

Design Features

Bolted cover.

Optional buffering damp structure

Renewable or and welded seat

Flanged or buttwelding ends

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier