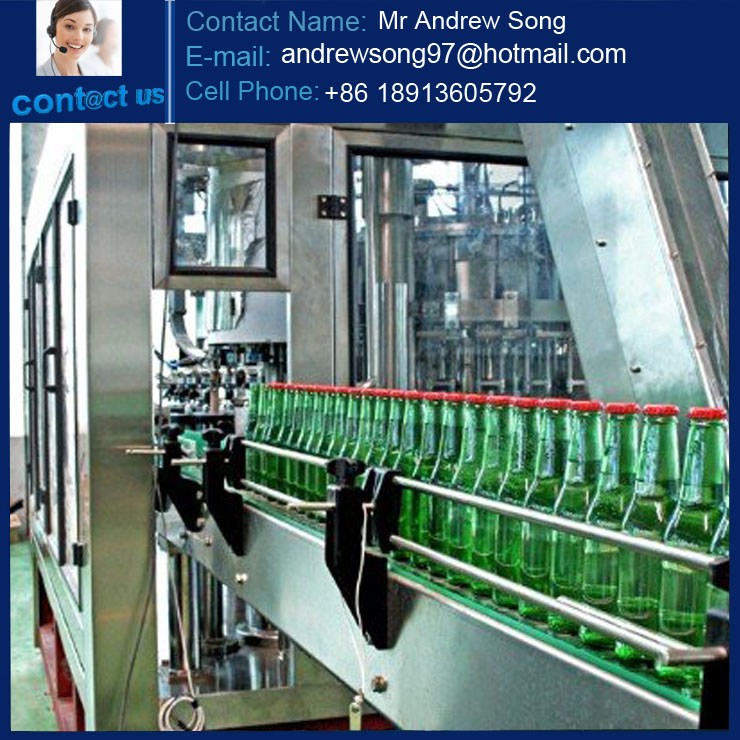

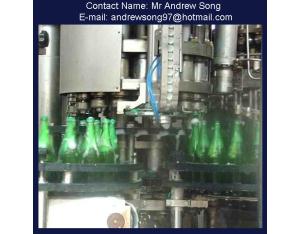

Automatic Glass Bottle Beer Filling Capping Bottling Machine

- Product Details

- Company Profile

1. The machine is a 3-in-1 integrated monoblock to reduce space-occupying. 2. The product (liquid) contacting parts are all made of 316L S. S with good quality, both interior and exterior parts of filling heads are polished, it is easy for cleaning. The seals in filling valve are imported parts with good heat-endurance and usage life as well as meeting requirements of food hygiene and hot filling. 3. The rinser apply the germfree water to rinse the bottle that ensure the high-level lustration of the bottle. 4. Adopting the high precision filling valve to provide high-speed filling and stable control on liquid level. 5. Special-designed neck-holding bottle conveying, filling valves will move up and down and bottles only rotate in horizontal level to guarantee stable conveying height to avoid product splash. 6. High-energy magnetic capping (torque is adjustable) to guarantee the capping effect and equipment adaptability.

Automatic Glass Bottle Beer Filling Capping Bottling Machine

1. The machine is a 3-in-1 integrated monoblock to reduce space-occupying.

2. The product (liquid) contacting parts are all made of 316L S. S with good quality, both interior and exterior parts of filling heads are polished, it is easy for cleaning. The seals in filling valve are imported parts with good heat-endurance and usage life as well as meeting requirements of food hygiene and hot filling.

3. The rinser apply the germfree water to rinse the bottle that ensure the high-level lustration of the bottle.

4. Adopting the high precision filling valve to provide high-speed filling and stable control on liquid level.

5. Special-designed neck-holding bottle conveying, filling valves will move up and down and bottles only rotate in horizontal level to guarantee stable conveying height to avoid product splash.

6. High-energy magnetic capping (torque is adjustable) to guarantee the capping effect and equipment adaptability.

Capacity: 6000-36000 BPH

Parameters:

| Model | CGFB16-16-6 | CGFB18-18-6 | CGFB24-24-8 | CGFB32-32-12 | CGFB40-40-12 |

| Capacity(BPH) | 2000-4000 | 4000-6000 | 6000-8000 | 8000-12000 | 12000-15000 |

| Washing head | 16 | 18 | 24 | 32 | 40 |

| Filling head | 16 | 18 | 24 | 32 | 40 |

| Capping head | 6 | 6 | 8 | 12 | 12 |

| Bottle diameter | 50-110mm | 50-110mm | 50-110mm | 50-110mm | 50-110mm |

| Bottle height | 150-340mm | 150-340mm | 150-340mm | 150-340mm | 150-340mm |

| Overall size | 2130x1700x2350 | 2450x1800x2350 | 2780x2200x2350 | 3600x2650x2350 | 4550×2650×2400 |

| Weight | 2000kg | 2500kg | 3200kg | 4500kg | 5600 |

.jpg)

.jpg)

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier