Self-retaining Hole High-Level Palletizing System

- Product Details

- Company Profile

Self-retaining Hole High-Level Palletizing System

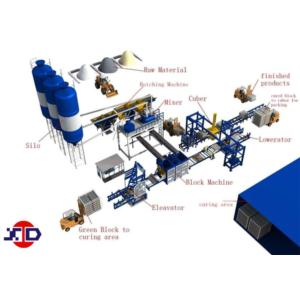

This palletizing production line is suitable for dry product palletizing of simple block production line. It is a semi-automatic palletizing production line. Under normal circumstance, it is set independently in the vicinity of product maintenance yard. For the curd blocks,it can be stacked on the spot.It also can work can work as part of the fully automatic block producing line.

The automatic palletizing system can separate bricks and paltes of different types and different specifications produced by different types of brick machines, and finally from a square of about one meter for cross-stacking, and can automatically generate forks Brick hole position as need. The stacking height can be up to 1400mm. After the palletizing is completed, the block stacking will be sent by the heavy -duty chain conveyor, which can be manually packed or matched with an automatic baler. Each node on the entire production line has a pre-stored position to save the forklift running time.

The whole system adopts PLC + touch screen control, cooperates with laser sensor + intelligent sensor to realize unmanned automatic operation, automatically stops the alarm and displays the fault location when out of order,it can be easily eliminated without professional technical. with remote control system + cloud data equipment manufacturers can solve all problems at the office allthe time . The operation of the equipment is controlled by electricity, air and hydraulic respectively.They don't interfere with each other and act coherently.It can be palletizing in about 16s,and about 15000pieces per day(standard brick).

XD-1200B Automatic Blocks Stacking Machine.

No. | Specification | Name | QTY | Remark |

1 | XD-1200 | Products Feeder | 1 | The forklift moves the entire block onto the products feeder, Then Elevator lift one layer block at a time to the next step. |

2 | XD-1200 | Elevator | 1 | |

3 | XD-1200 | pushing pallet device | 1 | The block and pallet are separating by pushing block device 1 and pushing pallet device. |

4 | XD-1200 | pushing Block device 1 | 1 | |

5 | XD-1200 | pushing Block device 2 | 1 | According to the arrangement of different block, the block are arranged into the set size automatically, and rotated after finishing to prepare staggered stacking. |

6 | XD-1200 | pushing and turning Block device | 1 | |

7 | XD-1200 | gantry stacker Clamps | 1 | Stacking blocks on the Chain Conveyor。 |

8 | XD-1200 | Chain Conveyor | 1 | Transport the Stacking blocks |

9 | XD-1200 | Pallet Turning Device | 1 | Turning the pallet |

10 | XD-1200 | Lowerator | 1 | Lowerator lift one layer pallet at a time to pallet conveyor |

11 | XD-1200 | Pallet Conveyor | 1 | |

12 | XD-1200 | shipping pallet magazine | 1 | Place shipping pallet on chain conveyor |

13 | XD-1200 | Hydraulic System | 2 |

|

14 | XD-1200 | Central Control System | 2 |

Power list | ||

NO. | Name | Power |

1 | Lifting machine travel motor | 1.5kw |

2 | Lift motor | 2.2 kw |

3 | Flipper motor | 0.75 kw |

4 | Brick machine motor | 2.2 kw |

5 | Small fuel tank | 3 kw |

6 | Second push motor | 1.5 kw |

7 | Third push motor | 1.5 kw |

8 | Large fuel tank | 15 kw |

9 | Brick machine motor | 5.5 kw |

10 | Air compressor | 7.5 kw |

Total Power | 45.65 kw | |

Main Technical parameter

- 1、Entire Area:~19000×10000(mm)Device Maximum:5000mm

- 2、 Total weight:~1800Kg

- 3、 Stacking Specifications:1000×1000(mm)

Standard solid brick layer 48 pieces,Stack 936 pieces

- 4、 Operating cycle:15—18seconds/layer

- 5、Total power:35Kw

- 6、Maximum Stack size:1500(mm)

Experience Member

Experience Member 0

0 Chinese

Supplier

Chinese

Supplier