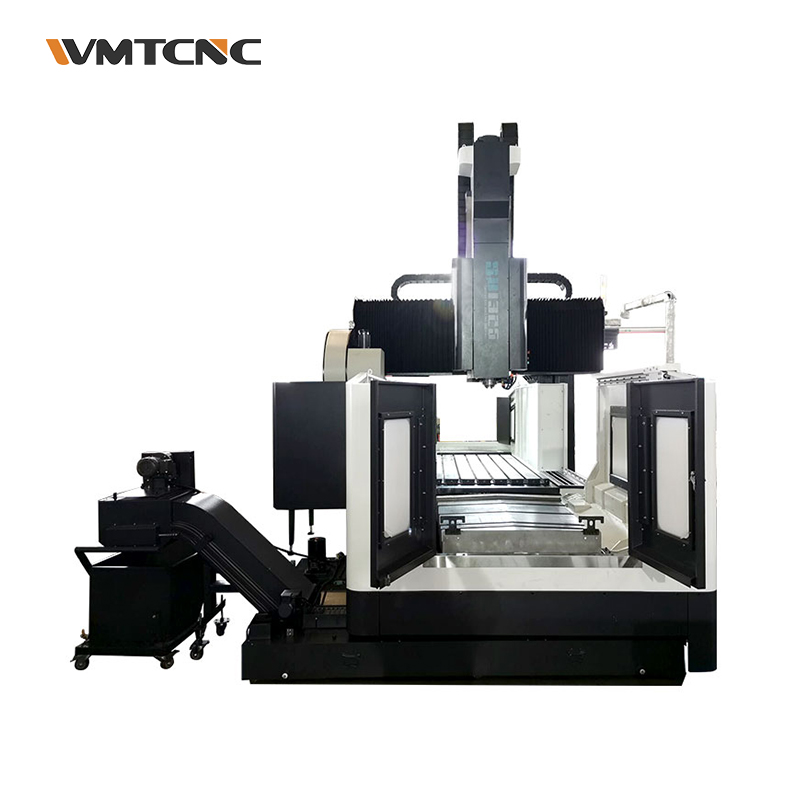

Double Column Machining Center

- Product Details

- Company Profile

1.Quick return:High performance cost ratio. 2.Energy saving: Energy consumption decrease by 20%;high stability. 3.Exclusive Interface: Easy to operation,programming and maintenance.

Features:

1.Quick return:High performance cost ratio.

2.Energy saving: Energy consumption decrease by 20%;high stability.

3.Exclusive Interface: Easy to operation,programming and maintenance.

More details about configuration:

1.In line with design concept of driven at the center of gravity,

the machine equipped with double balance counter weight.

Meanwhile the center of ram falls on the center of axis,with equalized ram guide-way allocation.

The design eliminates bending of ram guide-way when ram moves up and down

Consequently Z axis can perform with high stability and accuracy.

2.Direct connection of main motor.

3.It is equipped with oil chiller,cycle cooling source for spindle unit and motor carbine.

4.The hydraulic station,power source for balancing cylinder and spindle tool clamping and unclamping.

5.Lubrication station is controlled by CNC system which can test and alarm automatically.

| Specification | SP1325 |

| Worktable | |

| Worktable size(LXW) | 2500X1100MM |

| T-slots size(NXWXD) | 7X22X160MM |

| Travel | |

| X/Y/Z axis travel | 2600/1400/800MM |

| Capacity | |

| Distance from spindle nose to worktable surface | 150-950MM |

| Spindle | |

| Spindle taper | BT50 |

| Spindle power | 15/18.5KW |

| Max. spindle speed | 6000RPM(direct drive) |

| Feed(direct drive) | |

| Rapid feed speed(X/Y/Z) | 12/12/10 m/min |

| Ball screw(diameter+lead) | |

| X/Y/Z axis ball screw | 6316/5016/5016 |

| X/Y/Z guideway type | X/Y:roller linear guideways;Z:box guideway |

| Tool magazine | |

| Tool magazine capacity | 24T |

| Max.length of tool | 350M |

| Tool change time(T-T) | 3S |

| Positioning accuracy(GB standard) | |

| Positioning accuracy | 0.02/1000MM |

| RE-Positioning accuracy | 0.012MM |

| Machine dimension | |

| LXWXH | 7800X5500X5000MM |

| Machine weight | |

| Max. loading of worktable | 4T |

| N.W. | 21T |

Experience Member

Experience Member 0

0 Chinese

Supplier

Chinese

Supplier