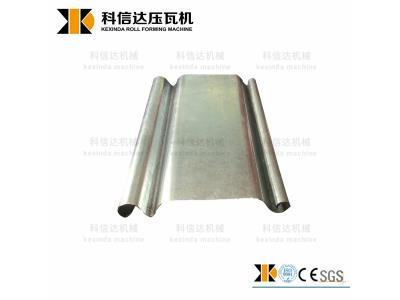

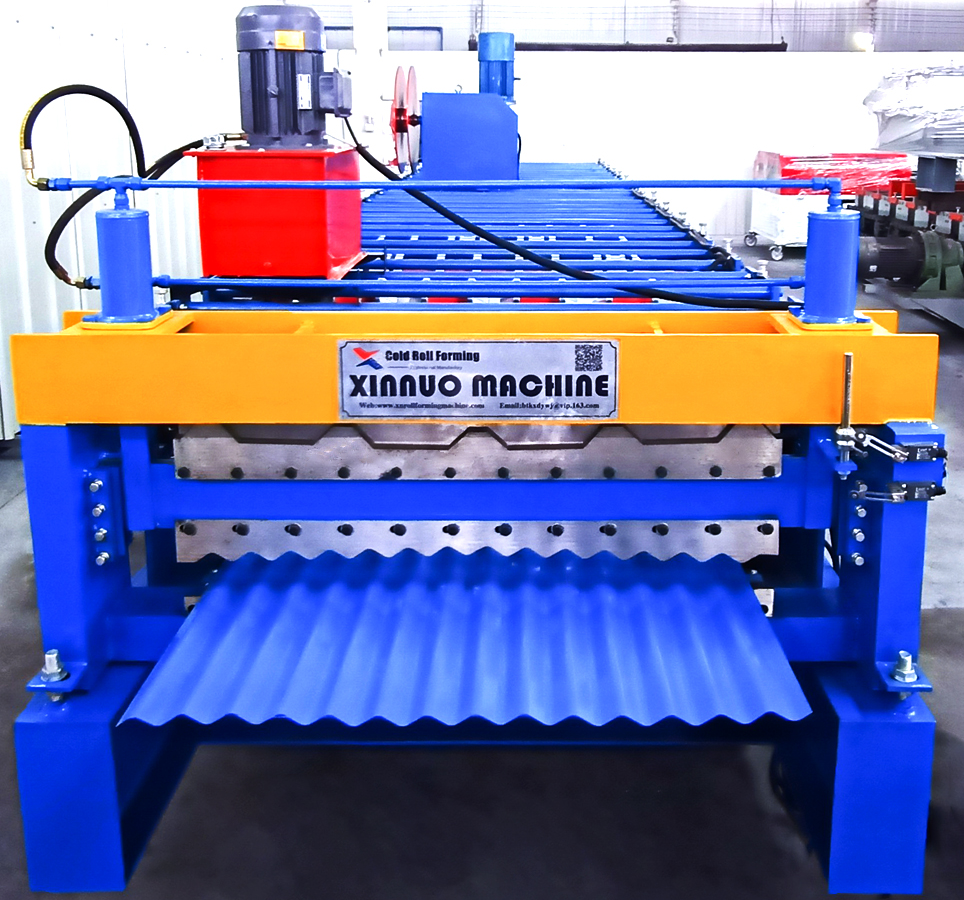

Double Layer Roll Forming Machine Wall Panel Tile Making Machine

- Product Details

- Company Profile

Double layer roll forming machine with the capable of forming a limited site area in two sections, and can quickly transform products, affordable, can be the perfect combination of the two models of devices into one, two plate replacement time becomes shorter, and also improve the rate of output.

1.

Double layer roll forming machine with the capable of forming a limited site area in two sections, and can quickly transform products, affordable, can be the perfect combination of the two models of devices into one, two plate replacement time becomes shorter, and also improve the rate of output.

Manual Un-coiler | Max Capacity: 5000kgs Inner diameter of coil: 400-600mm Manual with brake |

Leveling Device | Ensure the material level and straight |

Auto Main Forming System | Max Feeding width:1220 mm |

Hydraulic Cutting Device | Cutting way: pause to cut. |

Electrical System | Control system: HMI & PLC control panel. |

Run-out Table | Frame: 8# steel groove welded |

2. Processing flow diagram of our roof roll forming machine

Manual decoiler→→ Feeding material into machine →Roll forming machine →Measure length→Hydraulic cutting →Finished Products

PBR Panel metal roofing and siding is an ideal solution for pre-engineered metal, post-frame, and agricultural buildings. This metal roofing and siding panel is recommended for light commercial and industrial projects as well as consumer-based Do-It-Yourself (DIY) applications.

4. Why choose us - KXD roof sheet roll forming machine

We are Professional

We have more than 20 years manufacturing experience in cold roll forming machinery.

Our Business Ability

Till now, we have exported to more than 70 countries and areas. The main market is South America, Africa, Middle East, Eastern Europe, Southeast Asia. We also take part in different exhibitions allover the world.

All kinds of certificate

We get different kinds of certificate, like CE, ISO, SONCAP as so on, based on our strong quality, we are sure than we can meet your certificate requires.

6. After-sales Service

We can provide oversea after sales. Our engineers are availble to go to customer country to install the machine and training for u.

7.FAQ

1. You are the manuafacturer or trading company ?

A: We are the professional manufacturer , and we have more than 20 years professional experiece in the field of roll forming machine.

2. Can you make the machine according to my design or photo type?

A: Yes. We have an experienced team to work out the most suitable design and production plan

for the machine.

3. How can we be assured that you will deliver us quality machine with spare parts?

A:1. Customers to send the technical people to our factory for checking the quality.

2.We can send the technicians to the buyer`s factory for the installation of the machine.

4.What policy of your garentee?

A: Within the One-YEARS period, we could supply you the replacement parts free of charge

for any damaged parts caused by quality problems after two years,you need to buy by factory cost.

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier