GEBR. PFEIFFER vertical roller mill ceramic composite table liner supplier

- Product Details

- Company Profile

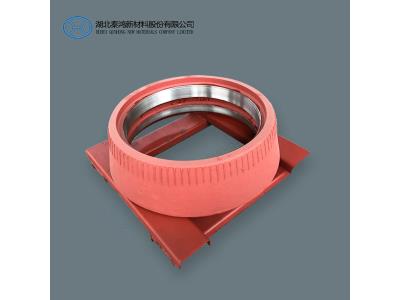

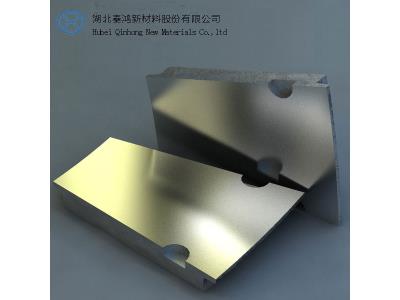

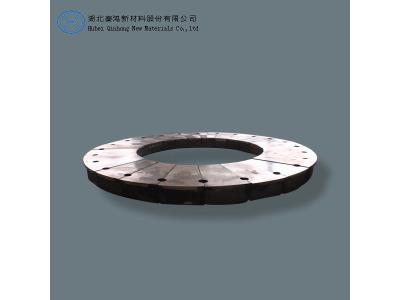

The special surface pit structure reduces the relative sliding of the working surface and the material, increases the vertical grinding output by about 5%, reduces the power consumption of vertical abrasion, and saves electricity costs; ? The working surface has high hardness, good wear resistance, ventilation resistance and vibration are also significantly reduced, the surface is uniform in the later wear period, and the vertical mill output is reduced less; ? The single-side service life is increased, twice the traditional material, grinding depth is less than 45mm, extending the working time of the vertical mill, can be used in reverse, reducing the number and time of maintenance, greatly saving maintenance costs; ? The internal material is mainly high chromium cast iron, which can be repaired by surfacing in the later wear stage, avoiding the cost of purchasing new rollers again and reducing the procurement cost.

Product describle:

1. The special surface pit structure reduces the relative sliding of the working surface and the material, increases the vertical grinding output by about 5%, reduces the electric consumption of vertical abrasion, and saves electricity costs;

2, high hardness of the working face, good wear resistance, reduce the number of maintenance, save maintenance costs;

3. The internal material is mainly high chromium cast iron, which can be repaired by surfacing in the later stage of wear to avoid purchasing new rollers again and reduce procurement costs.The ceramic wear-resistant layer can reach the edge of the wear-resistant parts and break through the forbidden zone where ceramics cannot be placed on the edge, thus extending the service life of the wear-resistant parts

Company introduce:

Established in 1993, our company has more than 20 years of wear-resistant material production history, and has more than 400 long-term cooperative users in cement, electric power and other industries. And with Citic Heavy Industries, Germany Feifan and many other mills at home and abroad supporting grinding machine wear-resistant parts, the company's main products: 1. Roller sleeve, roller skin, lining plate of grinding disc (composite surfacing, high chromium, cermet composite materials, etc.), grinding roll assembly; 2. Wear-resistant plate, roller press mechanism for repair; 3. Semi-automatic mill lining board, lining tile, ball mill lining board, vertical rotary mill lining board; 4. Crusher wear-resisting accessories, plate hammer, cermet composite hammer; 5. Auxiliary parts of mill crusher, etc.

Experience Member

Experience Member 0

0 Chinese

Supplier

Chinese

Supplier