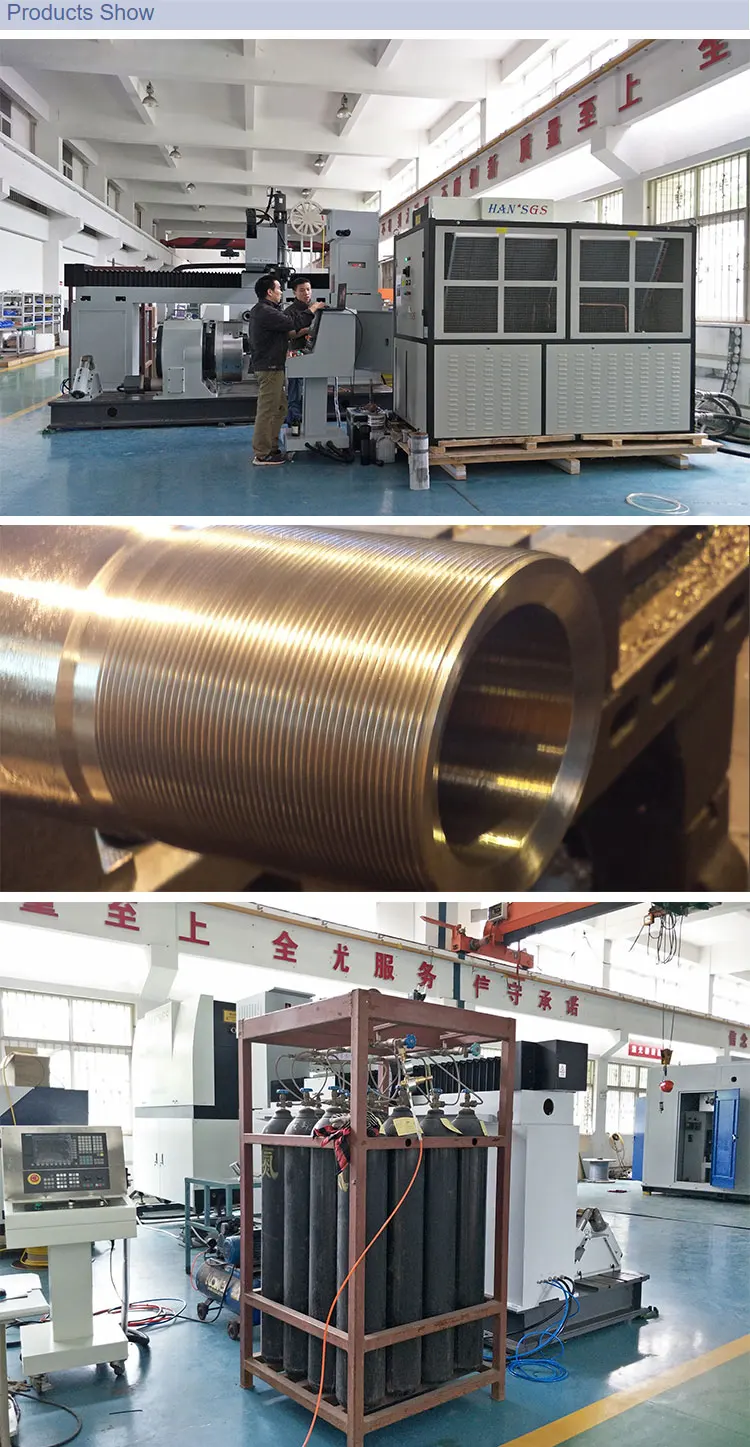

Column type parts laser repair processing Mining machinery laser cladding complete sets of equipment

- Product Details

- Company Profile

Laser cladding basic introduction Laser cladding refers to the placement of the selected coating material on the surface of the cladding substrate by means of different additive materials. Laser irradiation causes a thin layer of the substrate surface to melt at the same time, and after rapid solidification, the dilution is extremely low. Metallurgical combination of surface coating to improve the surface wear resistance, corrosion resistance, heat resistance, oxidation resistance and electrical characteristics of the process, to achieve the purpose of surface modification or repair, not only to meet the specific surface properties of the material requirements And save a lot of valuable elements. Laser Cladding Technology Features 1. Laser cladding can be precisely controlled, and the composition and properties of the cladding layer mainly depend on the composition of the cladding material; 2. The microstructure of laser cladding layer is dense, with few microscopic defects, high bonding strength and better performance; 3. The size and position of the laser cladding layer can be precisely controlled, and the width of a single laser cladding layer can reach 20-30 mm, and the maximum thickness of a single layer can reach more than 2 mm, so that the cladding efficiency and coating quality can be further improved; 4. The substrate does not require preheating, and the process is simple and reliable. 5. The laser cladding has no pollution to the environment and no radiation, and the working conditions have been greatly improved.

Column type parts laser repair processing Mining machinery laser cladding complete sets of equipment

Device Configuration:

1. High-power 10kW CO2 cross-flow laser and 80,000 kcal chillers set one by one

2. Five-axis and four-linked laser processing machine, Siemens 802D CNC system

3. It is equipped with an integrating mirror to make the light spot uniform to satisfy the function of laser hardening heat treatment.

4. With powder feeding device to meet the laser cladding function

Specification

The product is composed with TFL-6K/10K laser source, specific 60000 calories water chiller, CNC processing machine tool, auto powder delivery machine, optical path system and CNC control system.

| Model | GS-TFL-6K/10K | ||

| Laser source | TFL-6K/10K laser source/ semi-Laser source conductor laser source | ||

| Optical system | Fly optical path, Light path diameterφ70 | ||

| Manual type swing bald,Turning Angle±60°manual adjustment | |||

| CNC machine tools | |||

| model | 2 M | 2.5 M | 3.5 M |

| Working area (mm) | 2000*600*500 | 2500*1000*5000 | 3500*1000*500 |

| X, Y, Z axle working speed | 0 - 5000 m/min | ||

| Location accuracy | ±0.1 mm / 300 mm | ||

| Relocation accuracy | ±0.05 mm | ||

| Horizontal rotating table | |||

| Max. chuck diameter | Three claw Φ500/center height 500mm | Four claw Φ630/center height 690mm | Four claw Φ630/center height 800mm |

| Rotating speed | 0.5 - 15 rpm | 0.05 - 5 rpm | 0.05 - 5 rpm |

| Platform size(mm) | 3860 * 1450 * 280 | 5560 * 1000 * 280 | 7000 * 1200 * 350 |

| Center shaft | Bearing diameter Φ100-Φ350 one set | Bearing diameter Φ370-Φ630 two set s | Bearing diameter Φ370-Φ630 two set s |

| Max. Length of workpiece | 2500 mm | 3500 mm | 4000 mm |

| Max. Diameter of workpiece | Φ 800 |

Wuhan Hans Goldensky Laser System Co., Ltd.

Location:Wuhan,Hubei,China

Wuhan Hans Goldensky Laser System Co., Ltd is subsidiary company of Han's Laser Technology Industry Group Co., Ltd, (stock code: 002008). We are high-tech enterprise specialized in R&D, manufacture and sales for complete equipment of high-power laser source, laser cutting, laser welding, laser fusion covering, laser heat-processing and high-speed laser punching machine. We also provide automatic processing solving plans. | |

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier