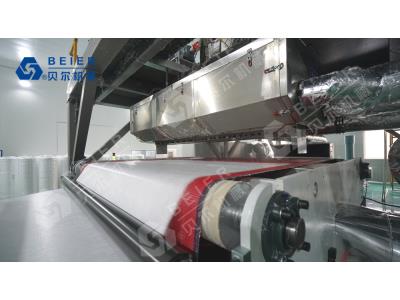

TSK Parallel Twin Screw Water-ring/Strand/Did-face Hot Cutting Pelletizing line

- Product Details

- Company Profile

TSK Twin Screw Extruder adopts modular design principle, component standardization manufacturing, which can present stable and reliable performance. Thanks to the modular principle, TSK extruders can provide highly customizable solutions according to customers' process and special requirements. Based on different output torque grade, TSK series extruders have basic type and efficiency type. Process section includes barrels, screw shafts, screw elements, individual temperature heating and cooling unit. Barrels and screw elements are designed in block principle. Block structure allows the screw elements combine and sequence optimized to realize the process: Conveying-Plasticization- Compounding & Dispersion- Homogenization- Degassing- Pressure building Also Block structure allows the barrels adjust freely to the fit the process requirement. Based on different process position, TSK extruders have different barrels type: feeding barrel, side feeding barrel, close barrel, open on top barrel, vacuum vent barrel, etc. According to the different jobs' requirement, barrels' materials can be nitride steel or bimetallic steel. Multiple cutting systems can be combined with TSK Twin Screw Extruder, such as strands pelletizing, hot-face cutting and under-water pelletizing, etc. Both Instrument control and PLC control are available to apply in the TSK electrical controlling system. All the key electrical parts adopt European brands to guarantee the controlling system with significant and stable performance.

Model | Screw Dia.(mm) | L/D | Motor Power (kw) | Capacity (kg/h) | Max Screw Speed (rpm) |

TSK-35 | 35.6 | 32-52 | 22 | 50-80 | 600 |

TSK-50 | 50.5 | 32-52 | 55 | 120-180 | 600 |

TSK-65 | 62.4 | 32-52 | 90-110 | 240-350 | 600 |

TSK-75 | 71.2 | 32-52 | 132-160 | 400-550 | 600 |

TSK-95 | 91 | 32-48 | 280-315 | 800-1100 | 500 |

Advantages of filler master batch

Reduce costs

Reduce product shrinkage

Increase the hardness of the product

Advantages of the production line

1.It can produce high-quality, high-quantity filler master batch

2.It works with high efficiency

3.It's computerized with high automation

3 kinds of Pelletizing methods:

1) Water-ring Pelletizing

2) Cold-strand Pelletizing

3) Die-face Hot-air Pelletizing

Application:

1. Master batch: PE,ABS,PS,EVA

2. Filling and modifying: PE\PP\EVA+ CaCO3, etc.

3. Blending and modifying: PC+ABS, PA+ABS, etc.

4. Glass fiber reinforcement: PP/PA + Glass Fibers

5. Cable materials

Experience Member

Experience Member 0

0 Chinese

Supplier

Chinese

Supplier